By selecting different materials, it can be applied to media such as water, sewage, seawater, air, steam, coal gas, combustible gases, corrosive media, oil products, and food, with a maximum working temperature of up to 600 ℃.

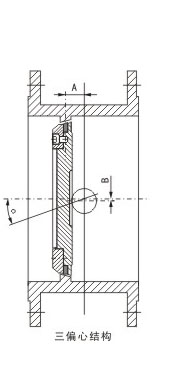

Triple eccentric structure: The axis of the valve stem is offset by a dimension A from the sealing surface of the butterfly plate, and offset by a dimension B from the axis of the valve body channel. The rotation axis of the valve seat forms an eccentric angle α with the axis of the valve body channel, thus forming triple eccentricity. When the butterfly valve is opened from 0 ° to 90 °, the sealing surface of the butterfly plate will immediately detach from the sealing surface of the valve seat at the moment of opening. When it is closed from 90 ° to 0 °, only at the moment of closing, the conical sealing surface of the butterfly plate will contact and press the conical seal of the valve seat. So there is no friction between the valve seat and the sealing surface on the butterfly plate, eliminating the possibility of wear and leakage.

Torque seal: The three eccentric structure causes the sealing pressure between the two sealing surfaces of the sealing pair to be generated by the driving torque applied to the valve stem when the butterfly valve is closed. Not only does it eliminate the decrease and disappearance of sealing pressure caused by aging, cold flow, and elastic failure of conventional elastic valve seat elastic materials, but it can also achieve arbitrary adjustment of its sealing pressure by changing the external driving torque, thereby improving the sealing performance of the three eccentric butterfly valve and greatly increasing its service life.

Soft hard laminated metal sealing structure: The butterfly plate sealing ring adopts a soft hard laminated stainless steel sheet and a flexible graphite plate sealing surface, which has the dual advantages of metal hard sealing and elastic sealing, and has excellent sealing performance under both low and high temperature conditions.

Bidirectional sealing: Due to the sealing surface cone angle being smaller than the friction angle of the sealing material, the butterfly plate immediately achieves self-locking when it is closed to the sealing position and can withstand a certain amount of reverse pressure impact.;

Fireproof structure: The all metal structure itself has the characteristic of fire safety.

Valve body sealing surface: Made of welded hard alloy or stainless steel, the sealing surface has high strength, good hardness, wear resistance, and can be opened and closed continuously for more than 60000 times without damage.

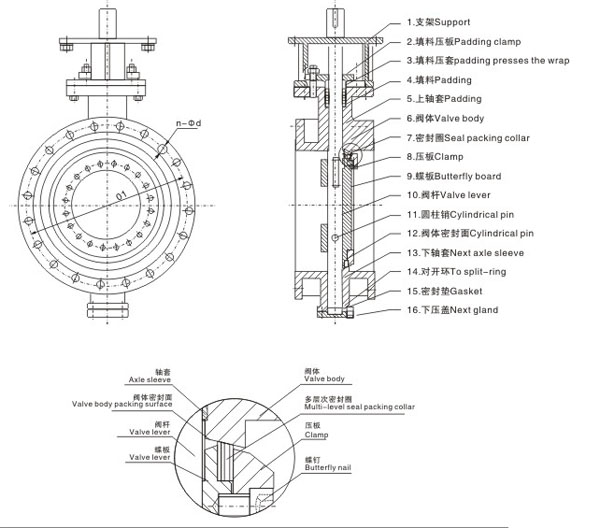

Sealing ring: The sealing ring is clamped onto the butterfly plate by a pressure plate, making it easy to install, adjust, and replace.

The upper and lower parts of the valve stem are equipped with shaft sleeves to prevent wear and adhesion, thereby improving its service life.

This product is flexible, labor-saving, convenient, and reliable to operate. The connection methods include flange, clamp, butt welding, and lug clamp. It can cut off the medium and adjust the medium flow rate arbitrarily.

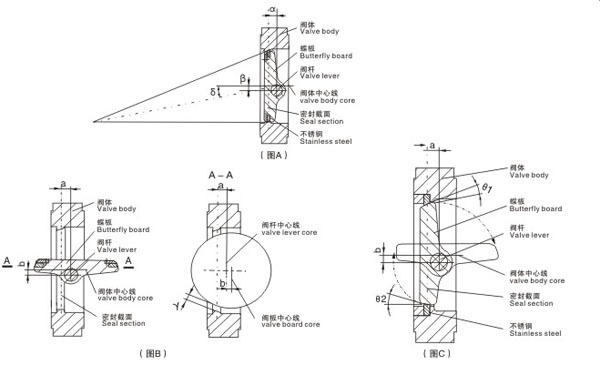

Due to the formation of a delta angle between the valve seat rotation axis and the valve body passage axis on the basis of the double eccentric sealing butterfly valve. The eccentricity result can be seen from the A-A sectional view in Figure B. When the three eccentric sealing butterfly valve is fully opened, its butterfly plate sealing surface will completely detach from the valve seat sealing surface and form a gap γ between the butterfly plate sealing surface and the valve body sealing surface. As shown in Figure C, the formation of the delta angle bias causes the large and small semicircles of the butterfly plate rotating with long and short radii to stick together. The tangent of the butterfly plate sealing rotation trajectory forms an angle of θ 1 and θ 2 with the valve seat sealing surface. When the butterfly valve is opened and closed, the sealing surface of the butterfly plate gradually disengages and gradually presses in. This completely eliminates the mechanical wear and scratches between the two sealing surfaces of the butterfly valve during its opening and closing time.

When this series of butterfly valves is opened from 0 ° to 90 °, the sealing surface of the butterfly plate will immediately detach from the sealing surface of the valve seat at the moment of opening. At the moment when it is closed from 90 ° to 0 °, the sealing surface of the butterfly plate will contact and press the sealing surface of the valve seat. As shown in Figure C, due to the formation of angles θ 1 and θ 2, when the butterfly valve is closed, the sealing pressure between the two sealing surfaces of its sealing pair is generated by the driving torque applied to the valve stem. Not only does it eliminate the decrease and disappearance of sealing pressure caused by aging of elastic seat elastic material, cold flow, and elastic failure in conventional eccentric butterfly valves, but it can also be adjusted arbitrarily by changing the external driving torque, thereby improving the sealing performance of the three eccentric sealing butterfly valve.

- Valve body material: carbon steel (WCB, WCC, LCB), chromium molybdenum steel (WC5, WC6, WC9), alloy steel, stainless steel (CF3, CF8, CF3M, CF8M, ZG1Cr18Ni9Ti, ZG1Cr18Ni12Mo2Ti)

- Internal material stainless steel (1Cr13, 2Cr13, 1Cr18Ni9, 1Cr18Ni9Ti, 1Cr18Ni12Mo2Ti, 304, 316, 304L, 316L) carbon steel chromium molybdenum steel special steel

- Connection forms: flange, clamp, butt welding, lug clamp

- Drive modes include manual, worm gear transmission, electric, pneumatic, hydraulic, electro-hydraulic linkage, etc

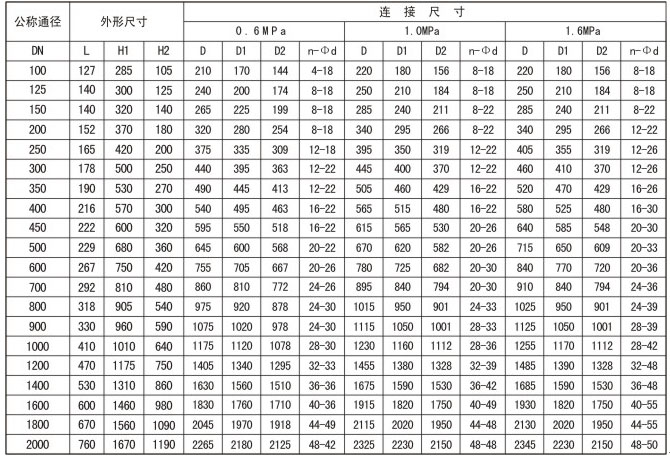

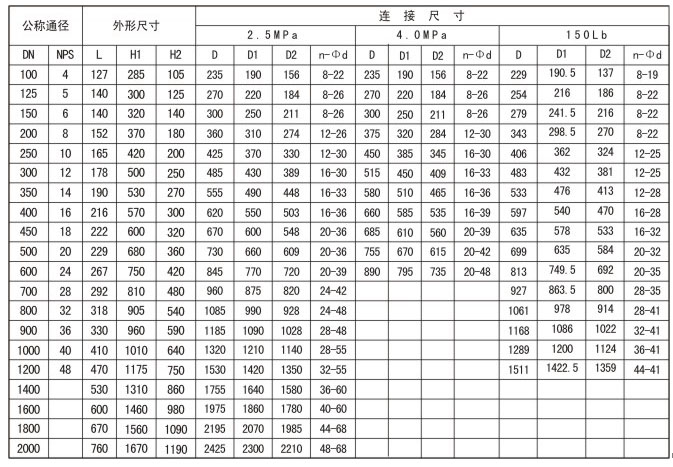

Main appearance and connection dimensions (flange type)

(1) Before installation, check that the product model, tag number, and specifications match the requirements. Inspect the entire valve for missing or loose parts.

(2) Prior to installation, clean the pipeline. Ensure there is sufficient straight pipe section at the valve inlet and install a filter. When connecting the valve body to the pipeline flanges, ensure coaxiality.

(3) Thoroughly clean the pipeline before installing the valve.

(4) The installation site should ensure the safety of personnel and equipment, facilitating operation, disassembly, and maintenance.

(5) The valve should be installed vertically upright on horizontal pipelines. If necessary, it can be installed at an angle, but horizontal installation should be avoided. For occasions with heavy valve weight or vibration, use a support frame.

(6) The medium flow direction must align with the arrow on the valve body. The air supply should be dry and oil-free. The valve should be used in environments with temperatures ranging from -20℃ to 55℃.

(1) Cleaning the Valve: For general media, cleaning with water is sufficient. For media harmful to health, first understand their properties and then select an appropriate cleaning method.

(2) Disassembly: Remove rust from exposed rusted parts first. Before derusting, protect the machined surfaces of precision parts such as the valve seat, valve plug, valve stem, and push rod. Use special tools when disassembling the valve seat.

(3) Valve Seat: Minor rust or wear on the sealing surface can be repaired by machining. If damage is severe, replace the seat. However, both repaired and replaced hard sealing surfaces must be lapped.

(4) Valve Stem: If the surface is damaged, it must be replaced.

(5) Damage to Push Rod, Guide, and Sealing Surfaces: Reverse-acting actuators must be replaced; direct-acting actuators can be reused after proper repair.

(6) Compression Spring: If there are cracks or other defects affecting strength, replace it immediately.

(7) Wear Parts: Packing, gaskets, and O-rings must be replaced entirely during each maintenance. Check the valve plug and diaphragm for cracks, aging, or corrosion that may cause future failures. Decide whether to replace them based on inspection results, but the diaphragm service life should not exceed 2-3 years.

(8) When reassembling the valve, ensure alignment. Tighten bolts diagonally and lubricate sliding parts. After reassembly, debug the valve according to the factory test items and methods. During this period, accurately adjust the packing compression force and the valve plug closing position.

-

If the model has not been selected before ordering, please provide us with the operating parameters:

(1) Nominal diameter DN (mm);

(2) Nominal pressure (MPa or bar);

(3) Fluid properties (including medium temperature, viscosity, or acidity/alkalinity);

(4) Pressure before and after the valve (pressure differential);

(5) Requirements for flow characteristics;

(6) Materials of valve body and valve core;

(7) Connection type;

(8) Driving method (provide air supply pressure, driving voltage);

(9) Supporting accessories (for pneumatic valves, it is recommended that users install an air filter triplet and a 2-position 5-way solenoid valve);

(10) On-site working conditions. -

If the product model of our company has been selected by the design unit, please order directly from our production department according to the model;

-

When the application occasion is very important or the pipeline is relatively complex, please provide the design drawings and detailed parameters as much as possible, and our experts will review and check them for you.